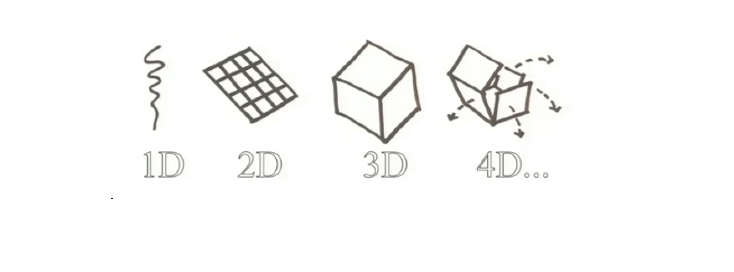

4D printing is the concept of 3D printed parts assembling themselves into an object, machine, or building. Skylar Tibbits, and MIT engineer, is researching the possibilites of 4D printing and creating items that can self-assemble, turning complex manufacturing and infrastructure processes to a simple version, thus saving time and money, and increasing worker safety.

4D printing would be useful in several applications, such as NASA building machines and buildings in space, using native materials on the moon or Mars. The technology could also be used in remote places where resources are few and far between or in harsh environments. This would allow the use of previously unavailable resources without the safety risk to human workers.

Watch Skylar's Ted Talk Video.

How 4D Printing Works

The idea is to print physical and biological material that is programmable and that can change shape, change properties, or compute without silicone. By using materail and geometry, environmental interactions, and energy, self-assembly is an exciting possibility of the future.

4D Printing Software

There is software called cadnano that allows users to design 3D models and use DNA to self-assemble. Autodesk has created software called Project Cyborg that allows users to simulate self-assembly behavior and optimize which parts are folding and when. The software can be used for both nano-scale and human self-assembly.

To learn more about the latest in 3D Printing, check out our 3D printing.