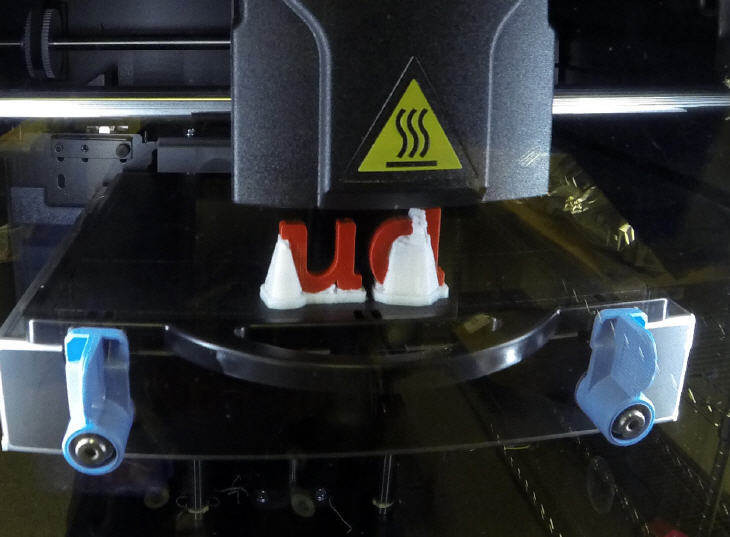

More commonly known as 3D printing, additive manufacturing is a process that uses a 3D printer to print a 3D object by adding material layer by layer. There are several techniques for printing, including melting material, such as plastic, and pushing it through a heated nozzle. fusing powders together to create an object, and laying down layers of resins, waxes, or other materials to build up a 3D object.

Possibilites of Additive Manufacturing

There are many applications for 3D printing, such as printing out small parts for, say, a refrigerator, designing haute couture fashion for a fashion show, personalizing bracelets and necklaces, or even creating works of chocolate art. The medical industry is already taking advantage of 3D printing to create replicas of bones and build medical implants. Archaeologists can scan fragile artifacts and print out a model. Kids can print models of bugs or airplanes or even create their own airship design. Fashionistas are already wearing the latest designs created by 3D printing. The options are limited only by the creator's imagination and exciting possibilities are cropping up everywhere.

How Additive Manufacturing Works

First, you create a 3D model on a 3D modeling program or scan an object with a 3D scanner. There are many how-to guides available and the software comes with instructions on creating models. Once you have created your design, save the file using an STL or OBJ file format, or other format compatible with the printer. Most 3D printers come with software to process and convert the files, preparing them to print. The printer's software slices the model into sections and determines how the printer will print each layer of the object. This process typically takes between 0 to 30 minutes depending on the geometry of the object, the 3D printer, and the speed of the the computer. Once this process is done, the printer melts or fuses the material and prints the object one layer at a time. You can watch the process of the object being printed, which is pretty neat to see. Printing can take a few minutes or several hours depending on the size and complexity of the object being printed.

Additive Manufacturing Commercial Products and Applications

MakerBot (now owed by Stratasys) creates 3D printers for home use and includes software to convert STL or OBJ files to X3G files. You will need 3D modeling software, such as CAD software in addition to the printer. The MakerBot printer allows home users to create one-of-a-kind products right at their desk. There are also commercial-grade printers, such as the ZPrinter 850 or the Stratasys Fortus 900mc. Currently, Microsoft is creating built-in support for 3D printers in their Windows software, which will make it even easier to print out 3D objects

What is the Future of Additive Manufacturing

As the technology improves and the cost goes down, 3D printing will go mainstream. Soon, it will be typical to have a 3D printer in the home to create anything from gadgets to goodies. Factories will use 3D printing to create small lots of parts or older parts that are no longer manufactured. Dentists will be able to use 3D printers to print out models of teeth in lieu of time-consuming casts. Customers will be able to create and customize any design that they can dream up. The forecasted revenue for 2016 is 3.1 billion dollars for 3D printing. For those of us who use this technology early, the benefits of 3D printing will happen fast and the rewards vast. Happy 3D printing!

To learn more about the latest in 3D Printing, check out our 3D printing.