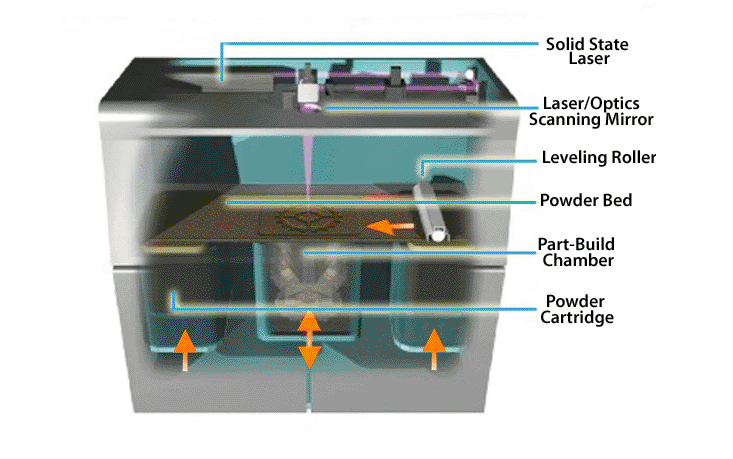

Like other 3D printing technologies, Direct Metal Printing (DMP) builds objects layer by layer in a process called additive manufacturing. A powerful fiber laser is directed at a layer of fine metal powder. The laser precisely and quickly melts the powder so the particles bind to each other. A new layer of powder is applied and the process repeats so each subsequent layer of material binds to the previous layer. This process guarantees the parts have a dense and homogenous material structure. Additionally, 3D printing can produce geometries that would be impossible to replicate using traditional manufacturing methods like casting or machining. Materials used in DMP 3D printing include aluminum, titanium, and stainless steel. A variety of finishes can be used during post processing on DMP parts. See also Direct Metal Laser Sintering (DMLS).

To learn more about the latest in 3D Printing, check out our 3D printing.