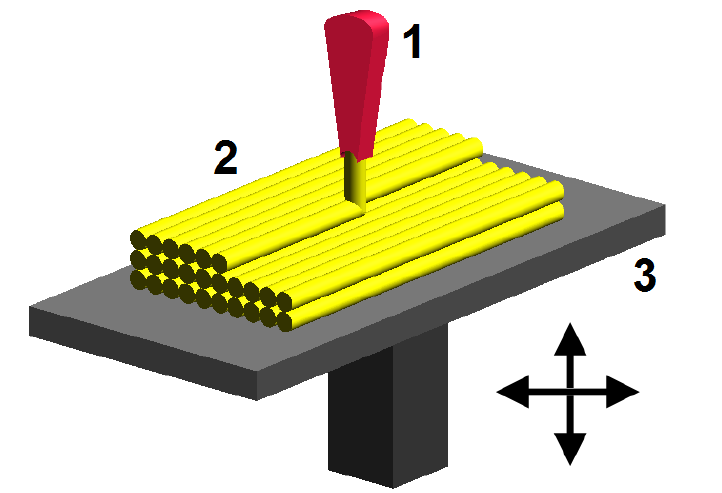

Extrusion 3D printing, also called Fused Deposition Modeling (FDM) is a 3D printing process that uses spools of plastic or metal filament that extrudes through a heated nozzle layer by layer to create a 3D part.

How Extrusion 3D Printing WorksFirst, the user creates a model using 3D software and saves it as an STL file. The STL file is then sent to the 3D printer's interfacing software where it slices the model into sections and determines how each layer will be printed. The model is then sent to the 3D printer. The metal or plastic filament is extruded through a heated nozzle layer by layer until the part is complete. A heated print bed ensures even cooling of the part and prevents the part from curling at the edges and warping.

History of Extrusion 3D PrintingScott Crump developed FDM in 1988 by using glue gun to extrude a mixture of polyethylene and candle wax to create a toy frog for his daughter. Crump created an automated system and patented the technology in 1989. He started the company Stratasys with his wife, Lisa, in the same year. The patent has expired and several DIY efforts have been made in 3D printing as well as a robust open-source community in RepRap.

To learn more about the latest in 3D Printing, check out our 3D printing.