Also called Fused Filament Fabrication (FFF), Fused Deposition Modeling (FDM) is an additive manufacturing process, also known as 3D printing. ABS an PLA plastics, certain metals, and ceramics are commonly used for FDM processes. Examples of 3D printers that use FDM technology are the Cube, the Mojo, the Buccaneer®, and the MakerBot Replicator 2X.

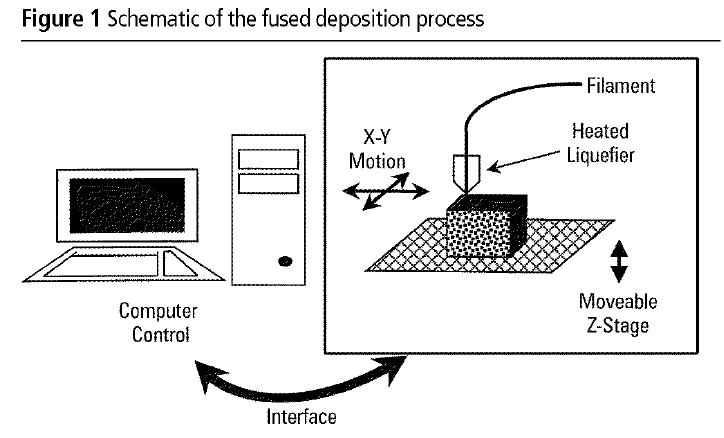

How Fused Deposition Modeling (FDM) WorksIn 3D printing, the user first creates a 3D model in a 3D modeling program, saves it as an STL file and the printer's interfacing software converts the file and slices the model into sections as well as determining how the layers will be printed. ONce the model is sent to the 3D printer, the build material is extruded through a heated nozzle layer by layer until the part is complete.

History of Fused Deposition Modeling (FDM)FDM technology was created in 1988 by Scott and Lisa Crump, the founders of Stratasys. Crump created the technology to build his daughter a toy frog using a glue gun and a mixture of polyethylene and candle wax. In 1989, Crump patented FDM technology and founded Stratasys. Stratasys created the software process that converts stereolithography (STL) files into another format to slice sections of the 3D model and determines how the layers will be printed.

To learn more about the latest in 3D Printing, check out our 3D printing.