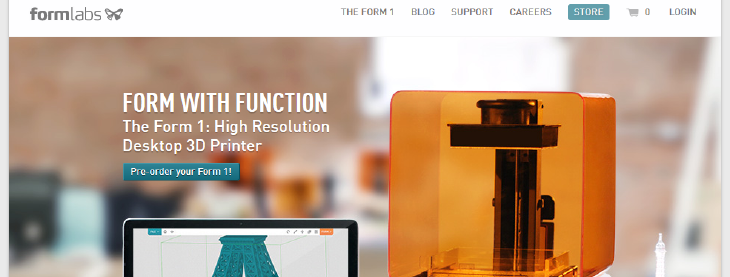

Formlabs is a 3D printing company. It has created a 3D printer dubbed the Form 1, which uses stereolithography to print 3D objects.

How the Form 1 3D Printer Works

The Form 1 uses stereolithography (SL) to 3D print objects. Stereolithography uses a photopolymer process in which liquid resin is exposed to an ultraviolet (UV) laser, which traces a layer of the 3D model image onto the resin. The exposure to light causes a layer of the resin to solidify. The build platform rises and the resin is again exposed to the laser. This process repeats until the part is complete. Formlabs uses in-house Acrylate Photopolymer resin with a professional finish.

Form 1 3D Printer Software

The interfacing software is called PreForm Software. This software converts STL files and slices the model into sections and determines how the layers will be printed. The software's features include automatic generation of smart support structures to build the part, Auto-Orient which rotates the part in the best possible position for support generation, manual tools for rotation, scaling, and duplication, and a 3D stage viewer to analyze individual print layers.

Form 1 3D Printer Form Finish Kit

The Form 1 includes a Form Finish Kit. The kit includes a finishing tray for components, a dipping basket for part transfer between finishing baths, a scraper to remove extra material, tongs to handle parts, and a drip trough with absorbent material.

Form 1 3D Printer Technical Specifications

To see technical specifications for the Form 1, click here.

History of Formlabs

Formlabs began in the MIT Media Lab in 2011. In 2012, Formlabs successfully created an affordable, quality 3D printer, the Form 1. The company was started with funding from Kickstarter. Before the Form 1 could be created, the company dealt with a lawsuit from 3D Systems over patent infringement. The two companies may end up settling out of court. In the meantime, Formlabs shipped out its Kickstarter orders.

To learn more about the latest in 3D Printing, check out our 3D printing.