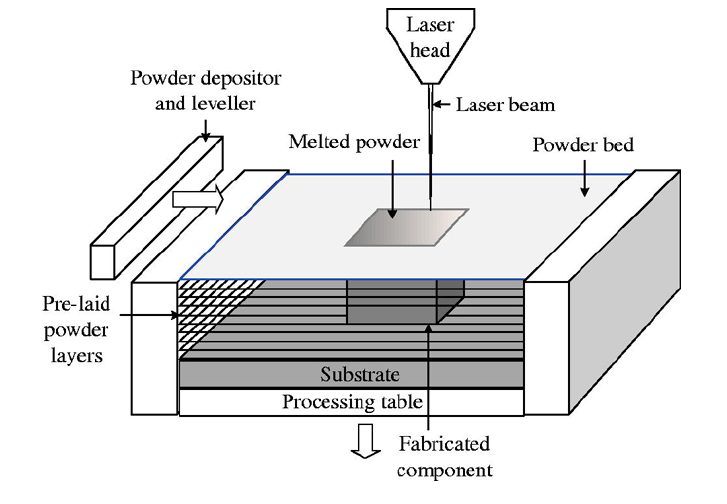

Granular 3D printing is an additive manufacturing technique that fuses material in a granular bed and moves downward to add another layer of granules until the part is complete. Granular 3D printing technology includes Selective Laser Melting (SLM), Electron Beam Melting® (EBM®), and inkjet 3D printing.

How Granular 3D Printing Works

First, the user creates a 3D model using 3D modeling software and saves it as an STL file. The file is sent to the 3D printer's interfacing software, which slices the model into sections and determines how the layers will be printed. Then material, such as plastic or ceramic powder, is fused in a granular bed layer by layer. The part is surrounded by layers of powders, which eliminates the need for support material. The process repeats until the part is complete.

To learn more about the latest in 3D Printing, check out our 3D printing.