Electrophoretic Deposition is a process in which the surface of an area is positively charged with liquid primer. The dunk tank is negatively charged. Once the object is placed in the dunk tank, the attraction of the primer is forced to the metal surface. This process is commonly used as a first-coat primer on automobiles. Previously, this process only allowed the entire surface to be primed. Now Researchers at Lawrence Livermore National Laboratory have created a process that allows specific, pre-determined surface areas to be treated, using a process called Light-directed Electrophoretic Deposition.

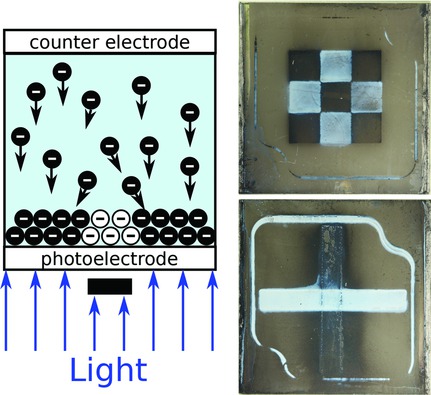

Light-directed Electrophoretic Deposition uses photoconductive electrodes and DC electrical fields to dynamically pattern surface material. Material builds up in targeted areas where the light comes in contact with the photoconductor's surface. This allows 3D patterns with multi-material composites over large surface areas with fine resolution.

Researchers produced an alumina ceramic-tungsten nano-particle composite. The tungsten nano-particles were deposited across the photoconductive surface, then illuminated through a laser-cut aluminum mask. Another mask was substituted along the material and deposited ceramic material.

This process can potentially move from depositing a single layer of material into a true additive manufacturing process.

"We have presented a novel electrophoretic deposition technique based on using light to pattern materials on a photoconductive layer. This represents a large step in advancing electrophoretic deposition as a method of fabricating complex 3D patterned composites," said Andrew Pascall, research engineer and lead author.

To learn more about the latest in 3D Printing, check out our 3D printing.