Support material in 3D printing is used as a sort of scaffolding to support a part as it is being printed. This allows parts that have design features, such as overhanging arches, to be supported until the material hardens. Without support material, certain types of designs would have the melted material oozing out of shape.

How It Works

The part material is extruded from a heated nozzle and then support material is extruded. The interfacing software converts STL or OBJ files into code that is read from the computer. This software also determines how the support material is printed out. Once the part is printed, the support material remains attached and must be removed by the user. There are several methods for removing support material: breaking it off, using chemicals to dissolve the material, washing the part with high-pressure water hoses, or lifing the part from powder support material and reusing the powder.

Materials Used

Gel-like Photopolymer: Gel-like photopolymers harden when exposed to ultraviolet (UV) light.

Polylactic Acid (PLA) Plastic: PLA plastic is thermoplastic that softens when heated up and hardens when cooled. Used as support material, it can be broken off to remove it.

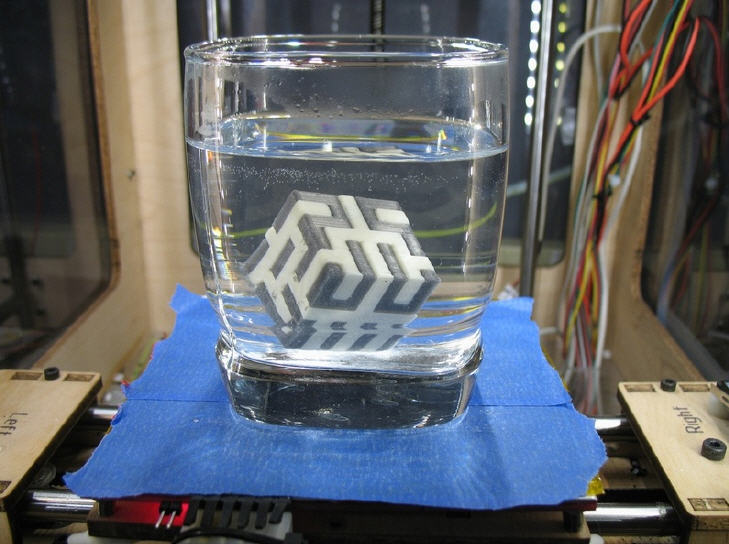

Polyvinyl Alcohol (PVA): PVA is a thermoplastic that is water-soluble. PVA support material can be removed by immersion in water, where it will break apart.

Powder: Selective Laser Sintering (SLS) or Direct Metal Laser Sintering (DMLS) use a powder as support material.

Methods of Removal

Breaking: Plastic support material can be snapped off by using hands or tools. Once the support material is removed, the user may need to sand the part to smooth out any marks created by the support material's removal.

Chemicals: Some support material can be dissolved with chemicals. This does present a hazard and isn't necessarily the ideal solution for removing support material.

High-pressure Water Hose: Gel-like support material can be removed with high-pressure water hoses.

Powder: Selective Laser Sintering (SLS) or Direct Metal Laser Sintering (DMLS) uses a powder as support material. Once the part is complete, the part can be lifted from the powder and the powder reused.

To learn more about the latest in 3D Printing, check out our 3D printing.