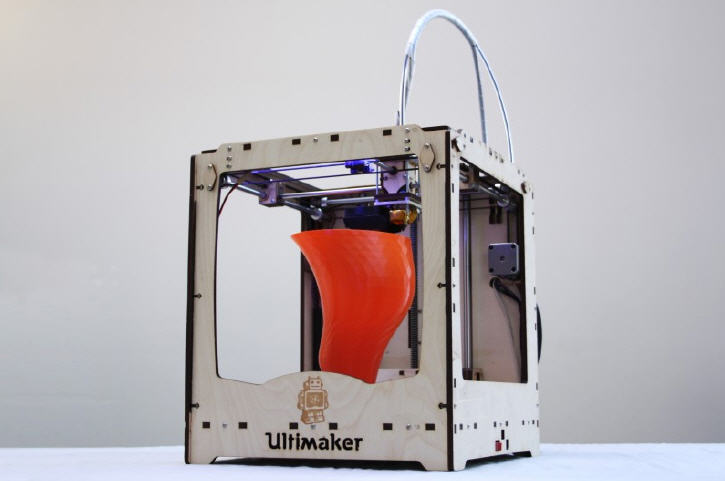

Ultimaker is a 3D printer created by Ultimaking Ltd. that uses RepRap open software. The Ultimaker comes either assembled or as an unassembled kit for a lower price. Some technical know-how is required to assembled the Ultimaker. The printer uses ABS and PLA plastic filament. The build platform is large at 21 L x 21 W x 20.5 H centimeters.

The Ultimaker users Fused Deposition Modeling (FDM) which heats plastic and distributes the material onto the print bed. Users must first create a 3D model, save it as an STL file, and convert the file into G-code using Cura, the printers interfacing software. ABS or PLA plastic filament is wound onto a spool and attached to the printer. Once the 3D model has been sent to the printer, the plastic extrudes through the heated nozzle layer by layer until the part is complete.

The Ultimaking website states that PLA plastic is biodegradable, and although this is true, it cannot be composted in the backyard. It is biodegradable only under the right circumstances, which would be in a facility for plant scraps that are turned into fertalizer by microbes and must reach 140 degrees for 10 days in order to compost the material.

The Dutch company was founded by Martijn Elserman, Erik de Bruijn, and Sier Wijnia. The Ultimaker began selling in 2011. David Braam was dissatified with the RepRap open interfacing software and develped the software, Cura, for the Ultimaker. Elserman had owned a 2D printing company and was interested in expanding to 3D printing. Bruijn develops software and electronics for the Ultimaker. Wijna has a degree in Mechanical Engineering and is the lab manager for the fab lab, Protospace.

To learn more about the latest in 3D Printing, check out our 3D printing.